North Little Rock Electric Engineering

The Engineering Department of North Little Rock Electric works to support and improve reliable electric service for our customers. Our design team designs new services and helps customers upgrade existing facilities to their expanding needs. The Substation and Vegetation Management teams work to improve the overall health of our system and maintain the core infrastructure of our system. The GIS team maintains the maps and connectivity models that drive the outage management and customer service systems that rely on their data. The Planning Engineers forecast the potential growth due to new and changing power technologies to ensure no matter what challenges arise, we can build and provide service to any expansion of our customer base and their needs. Below are examples of work that our engineering department handles!

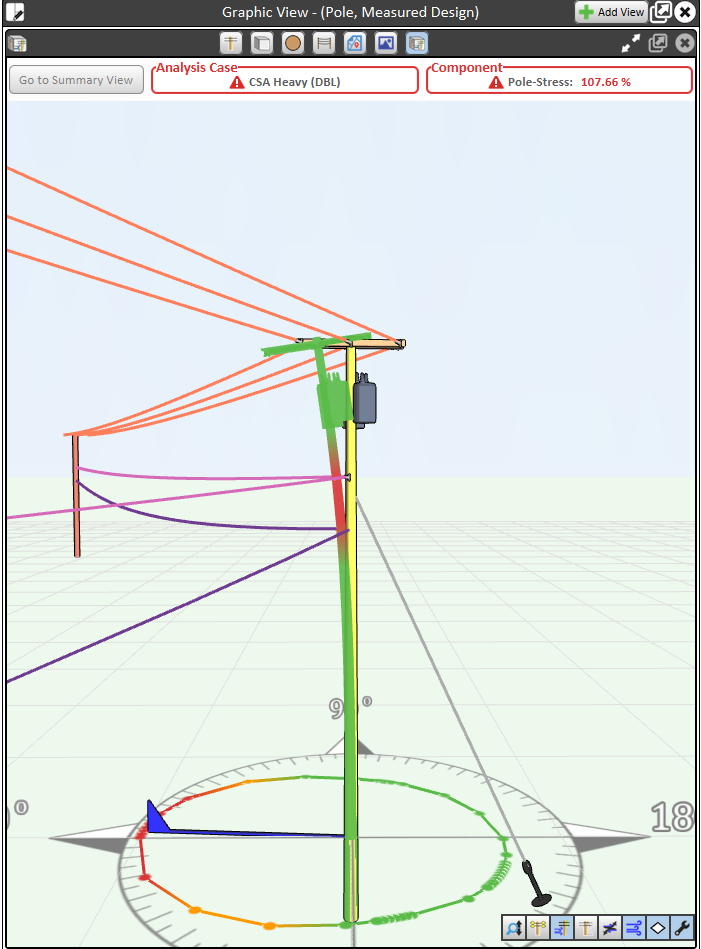

Design is one of the main functions of the Engineering Section of our department. Designers, engineers, and stakers act as project managers, customer support, and structural designers on a single work order. Typically jobs are begun to support the needs of new customers and the evolving needs of existing customers. As these small projects progress, designers interface with construction, warehouse, service, and accounting personnel.

Partner Software is our current staking software. It allows us to manage each work order through the design and construction process and helps with trueing up materials used and importing the new poles, wires, and customers into our master map model in Milsoft WindMilMap.

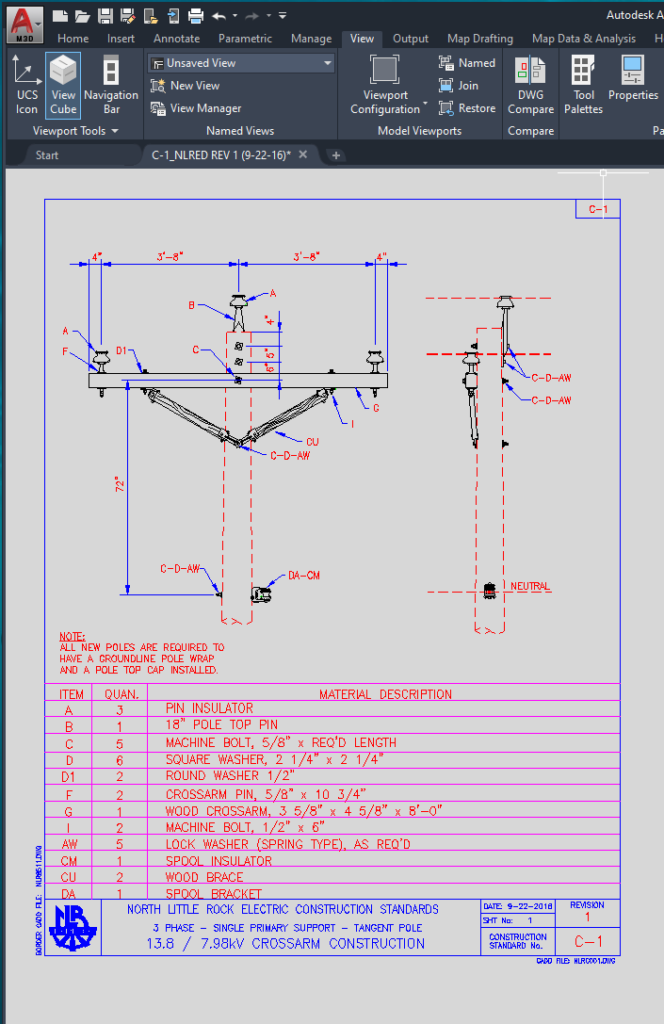

The NLR Electric Construction Standards are created in AutoCAD 2020 and are a maintained set of dwg files, images, reference drawings, and pdfs for use by our engineering and construction teams. These files are the main records of truth that our material lists and accounting records are based on. Each assembly unit is tied to the construction spacing defined in our computer engineering models, the list of materials that make up each assembly, and the accounting records that all of our continuing property records compile to measure the tens of millions of dollars that we have invested in our infrastructure that we maintain to support our community.

The NESC 2023 (National Electric Safety Code) drives the safety and construction standards we design and maintain. The clearance section of the book contains information on how close our wires can be to signs, buildings, and other utilities and above roads. The NESC is updated every five years, and the structural safety factors and guides in this book are applied and changed as this book evolves.

The NEC (National Electric Code) code takes precedence on the customer side of the meter. While it is a factor in our work, it is more important to the electricians and contractors who take our electric service and run the wiring in a home or business.

While electricity is invisible, we can observe and measure its effects with modern technologies. One of the best troubleshooting tools an electric utility worker can have is an infrared camera. When electricity flows outside a device’s normal operating standards or design standards, electricity loss manifests as heat emitted from that object. The infrared camera can detect this heat.

Once a year, the main lines of our electric distribution system are visually inspected with an IR camera to find and repair hotspots. Not only does this improve the reliability of our service, it saves us money. Every watt of electricity lost via heat in a bad connection or failing device is a watt that we lose revenue on to maintain the system. The losses prevented will easily pay for the $20,000 camera used to find these issues!

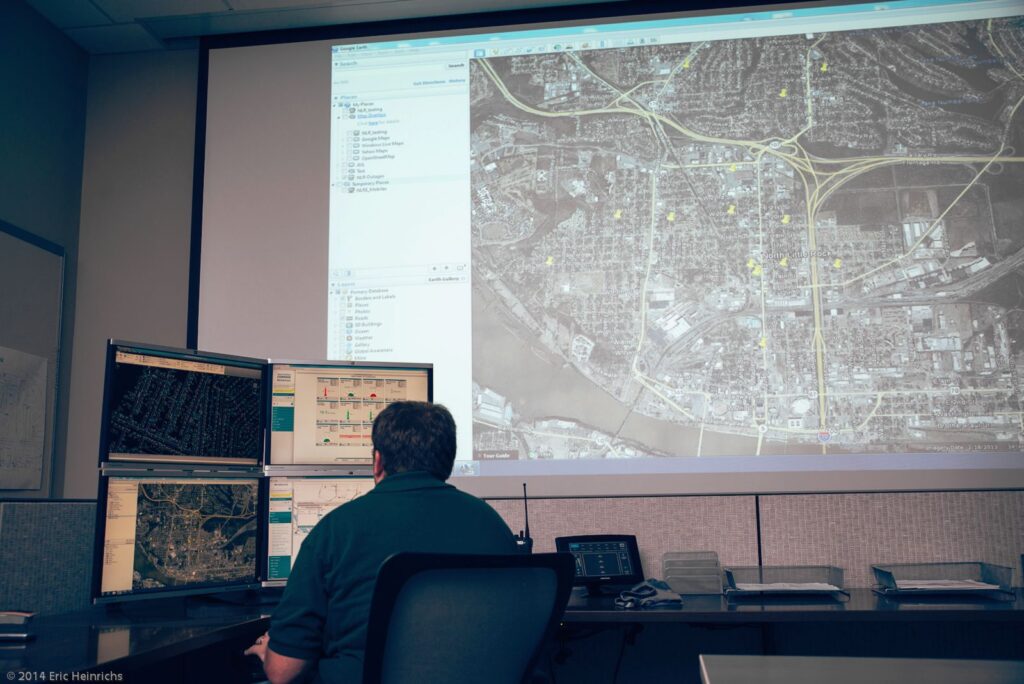

SCADA systems (System Control and Data Acquisition) are the heart of the daily operation, system reliability, and outage management efforts. These centralized control systems are connected over private IP networks and secured with end-to-end encryption protocols, good network design, and modern network security practices. While the physical security of our critical infrastructure is important, the rising growth of cybercrimes and hacking has pushed our industry into being one of the more conscious and more prepared for the eventual hacking attempts that occur from the global internet.

Everything comes back to mapping. It could be argued that the map data we capture, edit, and maintain is the most important system we are responsible for in our utility. The data in the map ensures the safety of our employees and the community and is the main record of truth that our planning decisions for future capital investment and daily operations rely on.

Modern GIS systems allow intelligence to be built into the electrical model of the wires and devices themselves. Selecting points and tracing what sources and loads stem from any conductor inside our system allows for faster troubleshooting and better visualization when problems occur.

Utilities strive for 100% reliability, but storms, animals, and even humans make this an unobtainable goal. Working an outage can be one of the most challenging but rewarding parts of working for a utility. It involves problem-solving and troubleshooting, balancing resources and speed, and impacting the lives of your fellow community members.

One of the top challenges facing our industry is the future of electric generation. While solar, hydro, and wind technologies have made a large dent in our fossil fuel reliance, they each have weaknesses. For example, when the sun isn’t shining or the wind isn’t blowing, electricity isn’t being generated.

Batteries are another stopgap in curving these technologies’ weaknesses but “mainstream” chemistry in these are still pretty large and toxic to construct. Future research must continue to strive for new technologies and innovations to achieve our reliable and renewable long-term energy needs and goals.